- Home

- Parts & Services

Metal Parts on Demand

Metal 3D Printing on Demand

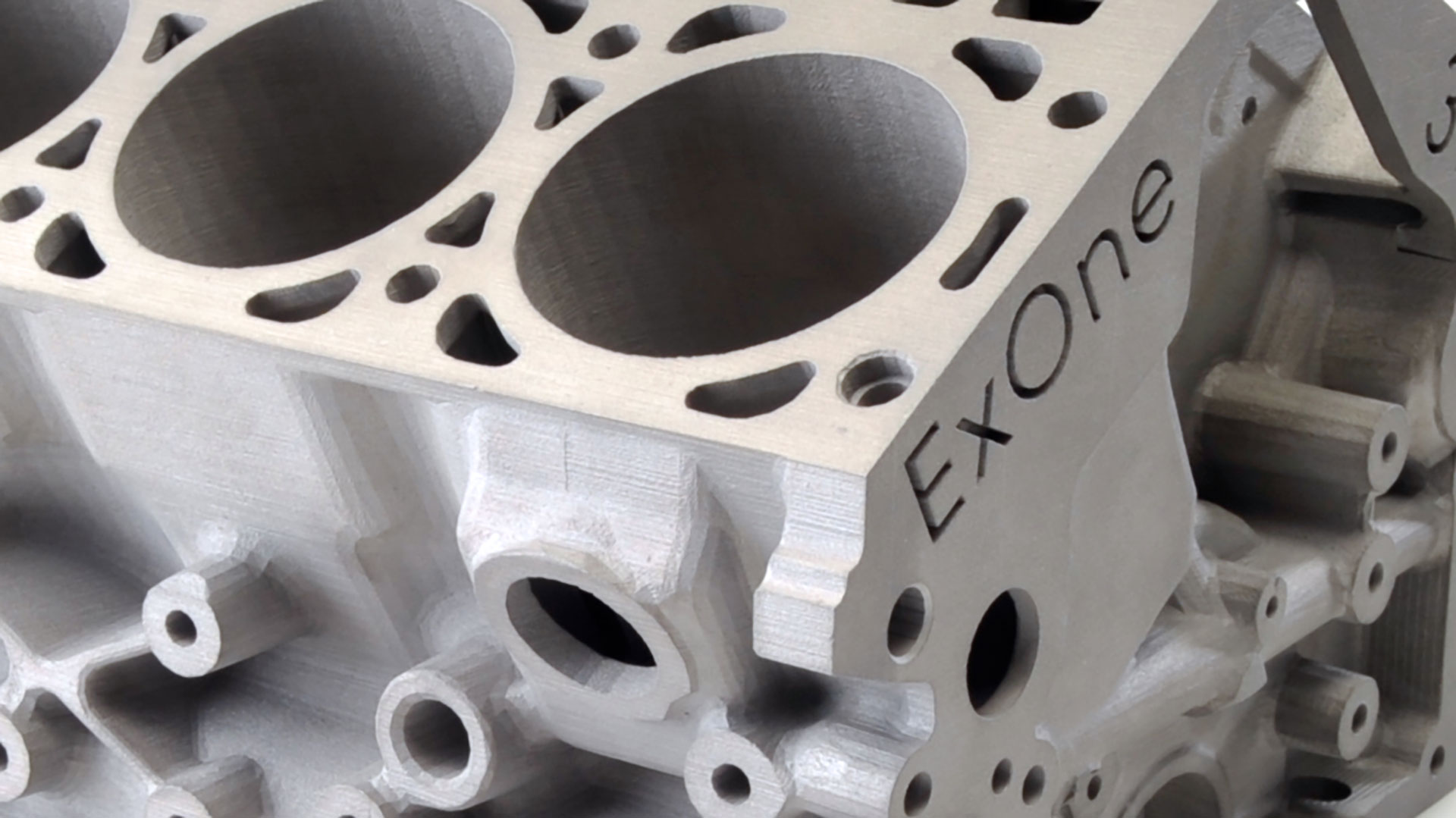

ExOne® Adoption Centers specialize in 3D printing metal parts. Using revolutionary binder jetting technology and industry-grade materials from traditional powder metallurgy feedstocks, we can work with you to determine the volume and timeframe required for the metal parts you need.

Manufacturing Design Guidelines

2020 Metal 3D Printing Manufacturing Design Guidelines

A Highly Customizable, Consistent Manufacturing Alternative

Metal 3D printing creates efficiencies by consistently printing parts to the exact specifications of your design file. And, since our process relies solely on the design file to direct production, your designers have the freedom to make quick adjustments to the file if you want to alter a component for the next run. Whether you’re testing prototypes or designing the next iteration of your product for full-scale manufacturing, ExOne metal 3D printing services can support your production requirements.

Metal 3D printing eliminates the need for tooling, support structures or build plates. This makes directly printing metal parts a fast and cost-effective method of serial production when compared to both traditional and other additive processes. Our metal 3D printing materials are designed to work with existing industry processes so the parts you receive are set up for system integration. Plus, our finishing capabilities mean your parts order is ready or near ready for direct commerce applications when you receive it.

Let ExOne 3D Print Your Metal Parts

Our high-quality service is fast and affordable. Many material options available.

Request quoteMetal Part Finishes

ExOne offers a variety of finishes for metal 3D printing.

View Our Finish OptionsOak Ridge National Laboratory

Over the past several years, we’ve worked with ExOne on four binder jetting systems and we’ve made exceptional progress in enhancing this additive manufacturing technique.

Amy Elliott, Oak Ridge National Laboratories Lead Researcher

ideas2cycles Leveraged ExOne’s Metal 3D Printing Service to Create Custom Metal Parts

3D metal printing made it easy for ideas2cycles to meet customer needs with reduced tooling and labor. Leveraging traditional manufacturing methods, custom bike parts require extensive manual labor and expensive tooling, but binder jetting technology can directly manufacture those same parts faster and more affordably. By 3D printing metal parts directly from design files, give our customers the freedom to focus on the creative elements of new designs.

Read Case StudyFAQs for 3D Printing Metal Parts on Demand

What are the benefits of binder jet 3D printing for metal production?

ExOne’s patented binder jetting technology for metal offers many benefits over traditional manufacturing, other forms of 3D printing and other binder jet offerings in the marketplace. Among them:

- Faster time to market. Go immediately from design file to production.

- Flexibility. 3D print a variety of metal powders on the same machine, and only print what you need. Smaller batches are affordable with a metal 3D printer.

- Waste reduction. Binder jet 3D printing offers a dramatic waste reduction over traditional manufacturing methods, and eliminates the support structures and build plates necessary with other forms of metal 3D printing.

- Rapid design changes. Modifying designs and iterating for performance improvements is easy and affordable with binder jet 3D printing.

- Exceptional design freedom. With the new design possibilities offered by binder jet 3D printing, you can consolidate parts, eliminate manufacturing processes, reduce weight and save energy. What’s more, 3D printing offers a new approach to solving new or nagging problems.

How do I know I need a printed metal part?

ExOne offers on-demand 3D printing for metal parts as well as sand castings and specialty materials. The most common application of our 3D metal printing is the manufacture of customized, complex parts. We can handle a variety of throughput requests from rapid product development to serial production, and have finishing options that will help you efficiently bring your part from conception to market. Our customers also leverage our 3D metal printing service to create prototypes or conceptual models.

Will I require finishing services when 3D printing metal parts?

ExOne® metal Parts on Demand are “near-net,” meaning some finishing may be desired or required. We offer a full array of finishing services that can be added to our on-demand metal 3D printing packages. Please contact us for details.

Will I need assistance with creating a digital file?

ExOne accepts a wide range of digital modeling file types, though STL is most preferred, and files can be easily uploaded via our Request a Quote form. If you need assistance creating a file, please inquire about our design services for 3D metal printing.

When will my parts be available?

Standard lead time for 3D printing metal parts is 10 working days, but will depend on the volume and complexity of the job. Rush services are available, so reach out to get a customized quote for 3D metal print service.

Can you accommodate the volume of my order?

Iterative or individually customized parts can be managed in a single print run, but 3D metal printing services are also available for serial production. Whether manufacturing lots of 1 or 1,000, the binder jetting process is the most economical choice for 3D printing metal Parts on Demand.

How do I access the manufacturing guidelines for metal sintered parts?

Click here to download the manufacturing design guidelines.

How do I access the manufacturing guidelines for metal infiltrated parts?

Click here to download the manufacturing guidelines.

Let ExOne 3D Print Your Metal Parts

Our high-quality service is fast and affordable. Many material options available.

request quote

.PNG?ext=.png)